Ointments for skis by temperature. Ski wax for wooden and plastic skis. How to lubricate cross-country skis

The most popular is skiing. In order to avoid problems during skiing, and the movement was comfortable, you need to take care of the equipment in advance. There are several options for special ski lubricants that need to be selected individually.

Why oil your skis?

This question arises among beginner skiers, since many consider this procedure unnecessary. During the ride, a friction force is created, which depends on the quality of the equipment and the condition of the snow. To reduce it, lubrication is carried out. There is another reason to lubricate wooden skis and equipment made of other materials, as the application of ointment prevents slipping back during the push. Thanks to the application of a special agent, the ski sticks well with the middle part to the snow. With the constant use of lubricants, you can extend the life of the inventory.

Which skis do not need to be lubricated?

There are different opinions regarding whether the preparation of equipment is mandatory. If we turn to the competent opinion of experts, then they, arguing about whether it is necessary to lubricate the skis, say that if you want to enjoy the perfect glide, then it is recommended to carry out a simple lubrication procedure before each walk. In addition, this will save the equipment for a long time.

How can you lubricate skis at home?

In shops and other points of sale you can find many different products designed for ski fans. If a person does not plan to deal with it seriously, then there will be no need to spend money on expensive formulations presented in the form of aerosols or branded paraffins. For those who are interested in how to lubricate skis for better glide, a wide range of different ointments is offered.

Such funds are presented in two forms: for better glide and grip. Beginning athletes can use universal sets of well-known brands: "Visti", "Swix" or "Briko". All products are color-coded according to the temperature at which they must be used. If the temperature is above zero, then liquid formulations are used. For negative values, the following classification applies:

- 0 to -2 - purple;

- -2 to -8 - blue;

- -5 to -12 - light green;

- -10 to -25 - dark green;

- -15 to -30 - black.

When figuring out how to lubricate skis, you need to pay attention to common paraffins, which, according to their properties, are divided into options for sliding and fixing. It is worth knowing how to lubricate the skis so that the snow does not stick in the absence of other means, so you can use wax and paraffin from candles, but medical is better. It is widely believed among the people that soap can be used, but in reality it will not be of any use.

How to lubricate skis at home?

To take care of your own equipment, you do not need to turn to specialists, because, knowing some of the subtleties, all procedures can be carried out independently at home. For those who are interested in how to properly lubricate skis, you should know that it is important to consider not only the material from which the equipment is made, but also the style of intended riding.

How to lubricate plastic skis?

If such equipment has been purchased, then it is necessary to apply lubricant to a clean and dry surface at room temperature. Understanding that, it is worth considering the basic rules:

- When using a solid ointment, apply it in several layers, rubbing each of them. After that, leave everything to cool, and the last layer is applied outdoors.

- It is recommended to conduct a test after walking a couple of kilometers, and if necessary, the agent must be changed. Those who are wondering why plastic skis need to be lubricated should know that without this, the glide will not be as good.

- For classic skiing, it is customary to apply paraffin or sliding ointments, but only on the back or front part, but the central area is lubricated with holding agents.

- When using paraffin, it is applied in drops, leveling them with an iron. After that, it is cooled and removed with a scraper. Finally, a nylon brush is applied.

- There is another important topic - how to lubricate plastic skis with a notch, and so such equipment does not require lubrication, but over time the notch is erased and then paraffin should be applied.

How and with what to lubricate semi-plastic skis?

This type of equipment is made of wood, but a plastic plate is applied on top of the sliding surface, which protects against wear. In operation, it is the same as for products made of plastic. For those who want to know how to lubricate the skis so that there is no kickback, then the recommendations described above for the plastic option should be used.

How to lubricate wooden skis?

In the presence of equipment made of wood, it will not be possible to do without lubrication, which is applied to a dry and clean surface. First you need to carry out priming, for which paraffin is used and it is better to take a candle-tablet. You need to rub harder, and then, walk on top with a hot iron. Excess that is not absorbed, remove cycles. This procedure should be carried out before each exit to the snow. Instructions on how to wax skis are as follows:

- Lay the gear down on a flat surface and clean it with a cloth.

- Hold the heated iron 2.5 cm above the skis and start processing from the edge. Apply some wax to the iron itself so that it melts and drips. Walk them over the entire surface.

- At the bottom, perform reciprocating movements with light pressure. The resulting layer of wax should harden, and then, using a scraper, remove it, moving from the highest point to the bottom.

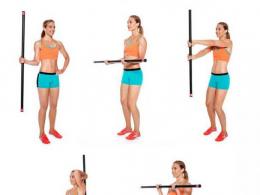

- An important step in the instruction on how to lubricate wooden skis is to brush the entire surface with a special brush, making only translational movements and applying a little pressure on the tool.

- For several hours, the skis must be taken out in the cold, and then left overnight at room temperature.

How to lubricate combination skis?

Some manufacturers have created special combination equipment that is suitable for both classic and free style. It is worth noting that you can meet them on the market less and less. To choose an easy way to lubricate your skis, you need to consider which running style will be used in a particular case. Processing schemes will be described below.

How to lubricate cross-country skis?

For amateur skiing, you can simply use special ointments that are selected depending on weather conditions. They should be 2-3 degrees higher than the temperature outside. Lubricate the block area with ointment, applying 2-3 layers, rubbing each with light movements. At the end, it is recommended to leave the equipment for 10-15 minutes. cool down. After skiing, using a scraper and a wash, the remnants of the product must be removed. The scheme of how to lubricate cross-country skis with paraffin is more complex.

- First they need to be fixed on a table or machine. At the first stage, the process of "hot" cleaning is carried out.

- Using an iron heated to the minimum melting temperature of paraffin, smooth out the melted grease. It is important not to delay.

- Without allowing the paraffin to set, scrape it off using a scraper and a stiff brush. The final layer should be 0.5-1 mm.

- After that, paraffin is applied, taking into account weather conditions. The procedure is similar to the steps described above, and after removing the remnants of the ski should cool for half an hour.

- Using a scraper or nylon brush, wax residues are removed, bringing the surface to a shine.

How to lubricate classic skis?

Fans of such skating should use slip and hold ointments. It is customary to apply the first on a sliding surface, and the second on a block (a section in the middle, which is determined from the heel of the boot plus 15-20 cm). For those who are interested in how to lubricate skis, you should know the following information:

- At the first stages of processing, cleaning is carried out, and then sliding ointment is applied.

- After that, treat the block with an ointment holder, which must be selected, focusing on the temperature and humidity of the snow.

- If it's warm, then use liquid products, and if it's cold, then use solid products. In the second case, a rubbing cork is used.

- It is important to consider that holding and sliding ointments should not be mixed.

- After applying the first layer, the product must be given time to grab, and only then re-lubrication is carried out.

- The preparation ends with polishing with a nylon brush.

- Another important point is how to lubricate the skis with paraffin, so it is applied only to the ends of the equipment.

How to lubricate skis for skating?

The processing of equipment for such riding is simpler, since only slip waxes are used. Not for professionals, one layer of ointment, selected by air temperature, is enough. As in the previously described processing schemes, the surface is cleaned. After that, you can proceed to the instructions, which relate to how to properly lubricate the skis at home:

- First, preheat the iron to the temperature indicated on the paraffin.

- Attach the bar to the surface of the iron and run it so that the drops of paraffin are evenly distributed.

- After that, run the iron from heel to toe to completely melt the paraffin. The fact that everything is done correctly will be evidenced by a uniform shine.

- An important step in the instructions on how to lubricate skis with paraffin at home is to remove the excess with a scraper after the layer has set. Move against the course of skating. Finish with polishing.

How to lubricate skis?

Before going out on the snow, it is necessary to carry out a hot treatment of the equipment, which will help to fill the pores. The procedure for how to lubricate skis is similar to the options described above. First, dirt and existing irregularities are cleaned. Be sure to grease everything with a degreaser. In the next step, apply the blue ointment in a hot way, and then, after it hardens, remove the excess with a scraper. You can also use liquid ointments that are distributed with a sponge.

Skiing (racing), or as they call it in Europe - flat skiing, involves moving on snow in two ways: classic and free (skating). In accordance with this, equipment manufacturers produce two main types of skis, classic (classic) and skating (skate), which has led to the existence of two main types of ski lubricants. The first type is sliding lubricants, the second is holding lubricants.

The main characteristics of lubricants sliding Ray "Ray"

Glide lubricants (ointments) are used to improve ski glide on snow, depending on weather conditions (mainly ambient temperature). On skating skis, they are applied over the entire surface in contact with snow. On classic skis, slip lubricants are applied only at the ends, excluding the middle part of the ski 50–60 centimeters long, where holding lubricants are applied. Glide lubricants are applied to the ski by rubbing. Solid lubricants are melted with a lubricating iron, allowing the ointment to drain onto the sliding surface. The lubricant applied to the ski is melted again with a lubricating iron until it is completely leveled. The difference of a special lubricating iron is a thick sole and an accurate thermostat that allows you to maintain the set temperature without big jumps. After the lubricant has cooled to ambient temperature, it is scraped off with a plastic scraper and polished with brushes with a variety of packings (nylon, natural hair, thin metal wire). After skiing on snow, grease residues are removed with special solvents.

Greases (ointments) sliding "Ray" are divided into several series. Which series to use depends on the humidity of the air and the presence of free water in the snow.

Series - CH carbon

Lubricants of this series do not contain fluoride additives. They are cheaper in price and have good performance in their ranges, especially at low air humidity. Designed for children's and veteran sports, tourism and provision of the training process for athletes of the highest ranks.

CH-1 +10−0*С yellow slip lubricant for wet, water skiing, strong thaw.

CH-2 +3−3*С red it is used for wet snow of any structure, at the beginning or end of a thaw in light frost.

CH-22 0−5*C orange glide lubricant for light frost, medium humidity, fine-grained and new snow. At high humidity it is combined with 0 +10*С.

CH-3 −2−7*С purple works perfectly in its temperature range on snow of any structure.

CH-4 - 6-12 * C blue one of the most versatile ointments, works well in its range at low and medium humidity on snow of any structure. Has excellent wear resistance. Serves as an excellent "preservative" in the preparation of skis for travel, due to the low melting point, wide temperature range and its versatility.

CH-5 −10−30*С green high-temperature synthetic paraffin (iron temperature for melting 150 * C), used at -10 * C and below in dry powdery or fine-grained frozen snow. The cycle is removed after melting in 2-3 minutes slightly warm. Cleaned with a stiff nylon brush, polished with non-woven material (fiberlene). At high air humidity (more than 80%), on new and falling snow, it is combined with SHF-77.78 powder. To do this, a thin layer of powder (about a third of the amount when the SHF is the final layer) is applied to warm, melted paraffin and re-fused together. Further processing is traditional. This lubrication option can be used in the range of -2-18 * C at high humidity.

Series - G graphite

Because of their anti-static properties, graphite-added lubricants often perform best in either dirty or low-humidity conditions. They can reduce the accumulation of dirt on the sliding surface of the ski and in wet snow.

GS(soft) +10−5*C soft antistatic - graphite, base in the range + 10−5*С.

GH(hard) −5−30*С frosty antistatic - graphite, can work independently at −5*С and below in conditions of low air humidity (less than 70%). Refractory (iron temperature for melting 150 * C), removed and processed similarly to CH-5 grease.

LFGS(soft) +10−5*C soft graphite grease with low "organofluorine" content. Mixed with compositions of "warm" temperature ranges, designed for conditions of medium humidity: dirty snow at positive temperatures, new and slightly stale at temperatures around zero and a slight minus.

LFGH(hard) −5−30*C frosty refractory "graphite" with a small content of "organofluorine". Possible basis for all ranges of ointments of the LF and HF series. Works independently at t below -7 * C, new snow and air humidity less than 70%. Processed in the same way as GH.

HFGS(soft) +10−5*C soft antistatic graphite with a high content of "fluorine", used as a base for high-fluorine paraffins, powders, accelerators, emulsions.

Series - LF low fluor

Lubricants LF are used in conditions of high humidity (more than 65%) and snow. The introduction of fluorine components into the composition significantly improves the speed characteristics and operational stability of the lubricant. The introduced fluorocomponents have a surface tension coefficient 2-3 times less than the hydrocarbon base.

LF-1 +10+1*C yellow fluorosilicone grease - the best conditions for use: wet, wet snow at + 3 * C and above. When using at a distance of more than 15 km, it is necessary to saturate with SHF powders, or apply them with a top layer.

LF-2 +3−3*C red it is used for wet snow of any structure, at the beginning or at the end of a thaw in light frost. Serves as a good base for SHF powders

LF-22 +5−2*C silvery.used for old, frozen, firn-like, dirty snow on both sides of zero. Solid, abrasion resistant lubricant, especially when combined with SHF-77 powder.

LF-3 −2−7*С purple works perfectly in its temperature range on snow of any structure. At high humidity (more than 80%) of the air, it can be used on new and fine-grained snow up to - 10 * C. The basic basis is graphite GH, LFGH.

LF-4 -6-12*C blue grease with a high content of synthetic components, universal, resistant to abrasion, especially "likes" new, falling snow of medium humidity in the range of -6-10 * C. Can serve as a base for all warmer HF series greases.

LF-5 −10−30*С green refractory, synthetic, slightly fluorinated paraffin for new fine-grained and frozen snow of medium and high humidity (60-85%). It is applied and processed similarly to CH-5.

LF-6 BASE soft service primer with a low fluorine content, iron melting temperature 120*C, used for cleaning (washing), priming new skis and skis after sanding. Perfectly penetrates into the pores of plastic, has excellent sliding characteristics, can work independently in the range of -1-10 * C and relative humidity of 65-85%. Designed for processing both cross-country and alpine skis.

Series - HF high fluor

Gliding ointments with a high content of low-melting organofluorine additives. They are unique in their excellent glide, operate over a wide temperature range and are resistant to abrasion and dirt. Ointments HF work great "alone", and even better in combination with SHF-77,78,100,200. Conditions of high humidity and sleet are ideal for HF waxes.

HF-1 +10+1*С yellow it is used in wet, wet, water-saturated snow, rain. At short distances (up to 20 km) it can work without the use of SHF powders.

HF-2 +3−3*С red universal slip lubricant on snow of any structure on both sides of 0 * C. Especially "loves" ------- a little stale snow with a humidity of more than 85%. Serves as a good base for powders of the SHF series.

HF-22 +5−2*C silvery used for coarse-grained dirty spring snow, firn, ice. Compared to HF-2, a more wear-resistant, abrasion-resistant sliding lubricant that has high speed characteristics in combination with SHF-77.

HF-3 −2−7*С purple works perfectly in its temperature range on snow of any structure at high humidity (more than 85%) of the air. The base base is better to use antistatic - graphite LFGH. The use of the final layer SHF-77 allows you to drive more than 50 km (on a prepared pair of skis) without compromising speed characteristics.

HF-4 −6−12*С blue a large percentage of solid synthetic additives gives the lubricant "resistance" to aggressive and already quite cold snow of any structure in conditions of high humidity (more than 85%) of the air. With new, falling snow, it is possible to use the final layer of SHF-78, on fine-grained snow - SHF-77.

HF-5 -5-25*C green fully synthetic refractory lubricant for cold snow and wet air. On old, as well as frozen snow, during warming, it is possible to use up to -2 * C.

Series - SHF 100% fluorocarbon

Powdered (emulsion), fluorocarbon, chemically inert sliding lubricants with a very low coefficient of friction. They have high resistance against dirt and oiling, and stability in work at long distances. Designed for high performance sports.

SHF-77 +10−10*С universal powder, for any snow structure in conditions of high humidity. The temperature of the iron for melting is 150*C.

SHF-78 +5−5*С powder can be used on snow of any structure (except for abrasive hard tracks). Especially "good" on new snow. The temperature of the iron for melting is 120 * C, which speaks for itself - there are no problems with overheating of the skis. Perfectly combined with soft paraffins.

SHF-100 +10+1*C emulsion fluorinated grease. It is effective in the presence of free water in the snow (slush, everything “floats”).

SHF-200 -2-15*C emulsion fluorinated grease. In its temperature range, it gives an increase in glide in any type of snow, even with medium humidity. On stale, fine-grained snow, colder than -8 * C can be much more effective than SHF-77 powder.

Technology of work with SHF-100, 200: apply thin layer on the surface of the skis, let dry, rub with a “cork” cork, then carefully polish with a soft nylon brush, fiberlen cloth.

The technology of working with SHF powders is similar to working with powders of this series of foreign firms. SHF greases are highly purified, non-toxic when heated up to 300*C. Do not work with an open flame, smoking in a room where work with fluorocarbon lubricants is carried out.

Methods for applying greases of the SHF series

Preliminary preparation: before applying powdered SHF lubricants, the skis must be treated with a sliding “paraffin”, ------- structure applied, ------ carefully brushed -------.

Hot way (reflow): apply a thin, even layer of powder, carefully spreading over the entire sliding surface of the ski. The iron should have a temperature of 150 * C, only in this case it is possible to melt the powder in one pass. The movement of the iron should be evenly calm (the formation of flickering sparks and crystals is a sign of melting and bonding of the SHF with the ski surface). After the skis have cooled, brushing follows: first with natural horsehair, then with soft nylon. Use "powder" brushes only for their intended purpose. This method of melting the powder is necessary when preparing skis for a distance of 30 km. and longer. Don't let the iron stop on the ski when melting the powder! Don't overheat your ski during melting - this can lead to a change in the structure of the plastic itself!

Dry application (rubbing): used for short distances (10-15 km) with soft snow structure on the track. A thin layer of powder is applied (can be islands, spots) and carefully rubbed with a clean cork or a special polishing felt block until a uniform film is formed. This is followed by brushing with horsehair, soft "powder" brush, fiberlen. If the distance is long enough (20-30 km.), And the snow is “abrasive”, and you doubt that the “organofluorine” will last until the end of the race, use an intermediate method between melting and dry rubbing the powder. Apply a little more SHF powder to the ski than with the dry method, rub the powder a little with a cork rub and go through it several times with an iron heated to 120 * C to make the ski warm. Then, carefully, with effort, rub the lubricant over the ski with a cork. Let the ski cool down and process it as in the hot process.

Paraffin saturation method: a thin layer of powder is applied to the melted paraffin (2-3 times less than with the hot method) and carefully, until flickering "stars" appear, it is heated with an iron. After cooling, the skis are processed in the traditional way. With refractory paraffins, SHF-77 is combined, with soft SHF-78. This method can be used in the range + 10-15 * C, which saves powder.

Ski preparation and choice of lubricant

New skis : if a “steinlift” is applied to the sliding surface - this is a microstructure for a certain temperature range and snow structure, then apply a service primer, melt, cool. After that, scrape the surface with a sharp metal cycle (with light pressure). Scraping remove only the villi, leaving a pattern of microstructure. It is necessary to treat the surface with a metal cycle only if the steinslift is of poor quality (hairy). Apply another layer of service primer (abundantly) - warm up, cool down, warm up again and after cooling, work with a sharply sharpened plastic scraper. Clean (in one direction from toe to heel) with a metal (bronze, brass) brush, then polish with a nylon brush. After that, depending on the weather, you can apply one of the "graphites", and the last layer of the main sliding paraffin.

If the skis are not new- treat them with a service primer (CH-22 can be used) to remove dirty and old grease; if the sliding surface is “rolled up” (skis have been used for a long time without updating the sliding plastic, “fluorine powders” were often used), cycle them lightly with a sharp metal scraper, then manually apply the structure. Next - lubrication for the weather.

snow structure, snow and air humidity, snow and air temperature, presence of wind and its speed, albedo (reflectivity) of the snow surface.

The main characteristics of lubricants for holding (clutch) Ray "Ray"

Lubricants (ointments) of holding are used on classic skis to prevent slippage of the ski when pushing forward. The holding lubricant application zone (block) starts from the heel of the boot and continues 50 - 60 centimeters forward to the toe of the ski. Holding lubricants also depend on weather conditions (mainly on ambient temperature).

Currently, skis with a wooden sliding surface are still used for snow skiing throughout Russia. Such skis are considered classic, for movement on them only holding lubricants are used, which are applied both under the block and over the entire sliding surface.

The holding lubricants have a sticky consistency, they are rubbed onto the skis in several layers, each layer is leveled with a special synthetic cork. The number of layers applied depends on weather conditions. The grease remaining after riding is removed with a plastic or metal scraper and washed off with a special solvent. Ray holding ointments are divided into two series.

Series of solid synthetic ointments W

Waxes of the W line are traditional holding waxes for any type of snow, designed for both athletes and amateurs. Today there are 9 items in this line, from the softest W-1 to the hardest W-9. A small step in temperature ranges, especially in the region of 0 * C, allows you to more carefully select the ointment in difficult weather conditions. Despite the fact that these ointments do not contain fluoride additives, they have a fairly wide range of applications, are easy to use, and can be easily combined with each other, with ointments from other lines and manufacturers.

W-1 +4+1*С yellow soft ointment, designed for thaw and wet, glossy tracks. Does not tolerate dry snow.

W-2 +2−0*С red special ointment for thaw weather. It is best applicable for stale fine-grained snow at a temperature slightly above zero.

W-3 0*C purple slightly harder than red ointment. Used around 0*C on new and fine-grained snow when it gets wet from cold.

W-4 0−2*С light purple suitable for use in any snow and light frost. With old, granular snow, it is possible to use up to -6 * C and as a basis for W-5.

W-5 -1-4*C blue universal, covering a wide range of temperatures below 0 * C, when used around 0 * C, it requires new snow and low humidity. On fine-grained snow, it works independently up to -12 * C. Wear-resistant.

W-6 -3-9*C light blue ointment for frosty weather and all types of snow.

W-7 -6-13*C green slightly harder than W-6 wax for new and old snow.

W-8 −10−18*С light green ointment for moderate frost. Suitable for covering softer waxes (required in a thin layer), especially on dry new snow to improve glide.

W-9 −15−30*С colorless ointment for critical frosty weather. Used mainly to coat softer waxes to improve ski glide. It is independently applied in thin layers on new powdered snow at an air temperature of -20 * C and colder.

Primer ointment

Ground wax is specially formulated to resist abrasion of hard holding waxes on rough, abrasive snow.

G +4 -25*C orange practical and flexible primer for all ointments at temperatures from +4*C and colder. It is recommended to use for old (granular) snow, when the ointment wears off quickly. It is applied under the iron and rubbed with a cork. Cooling down. The soil can be heated with a technical hair dryer and then rubbed with a cork. Next, an ointment of the appropriate temperature range is applied.

Series of solid resin ointments WG (terva)

Ointments of the WG line (terva - resin) - harmoniously complement the line of W ointments. Ointments of this group differ in composition from traditional ointments, which provides them with increased adhesion to snow in similar temperature ranges, and contain new simplified formulas. Today there are 6 items in this line, ranging from the softest WG-1 to the hardest WG-6. The addition of natural tree resin makes them especially “rollable” without compromising their holding properties on new and slightly old snow at low and medium air humidity. All ointments have a color from light to dark brown, visually differ only in the color of the label.

WG-1 +3−0*С yellow label for new wet, falling and stale snow, but at the same time not a glossy track. The warmer the weather, the thicker the ointment should be applied.

WG-2 +1−1*C red label for new and fine snow. The range of application can be much wider, from +2*С on new and dry snow to -2*С on old but not yet strongly recrystallized wet snow.

WG-3 0−3*C purple label universal holding ointment for slightly frosty weather. On stale snow, the range of application increases to -6 * C.

WG-4 -2-8*C blue label used for moderately cold snow of any structure. On new snow, it gives a confident hold already at -2 * C. On old snow with rounded crystals and low penetration power, combined with purple and red ointment.

WG-5 -5-12*C green label universal ointment for cold snow. The range of application on new and dry snow starts at -5*C and ends with old and transformed snow at -18*C. It is used as a primer under the increasingly "warm" ointments of this series.

WG-6 -10-25*C light green label the coldest, hardest ointment of the line. For snow of any structure in cold, extreme conditions.

A series of solid universal synthetic ointments WT

Waxes of the WT line are traditional holding waxes for any type of snow, intended mainly for amateurs. Ointments are universal and very easy to use, do not contain dyes, because they are difficult to confuse - one is soft, the other is hard. For a careful selection of grip lubricant for a ski race, it is better to use ointments of the series W or WG .

WТ-10 −1−12*С blue label universal, covering a wide range of temperatures below 0 * C, works independently up to -12 * C on any type of snow. Wear-resistant.

WТ-20 −8−25*С green label ointment for cold snow. Especially suitable for walking on dry new snow. For stale, frozen, very old snow, the first layer on the block must be applied with WT-10 ointment.

Ski preparation and clutch lubricant selection

Before starting lubrication, determine on the ski the area of \u200b\u200bthe surface on which the holding ointment will be applied. Usually it is located from the heel of the boot in the direction of the toe of the ski 50-60 cm ahead of the mount. This distance can be clearly defined already when buying skis, since the holding surface is the surface under which the piece of paper moves freely with an even distribution of the skier's body weight on both skis. Roughen the holding surface with 150-240 micron sandpaper. This will improve the adhesion of the ointment and make it work especially long. The first layer can be placed under the iron, thereby increasing the contact of the ointment with the surface of the ski and making the lubrication work longer. The heating temperature of the iron is about 120 * C. On abrading snow, use primer G as the first coat. Choose a holding wax according to the weather. Apply several thin coats to chilled skis, corking each coat thoroughly.

The main factors affecting the selection of lubricant: snow structure, snow and air temperature, snow and air humidity, presence of wind and its speed, albedo (reflectivity) of the snow surface.

Using SHF lubricants with clutch lubricants:

Powders of the SHF series can be used when working with clutch lubricants at "classic" distances. Especially successfully they are combined with semi-solid, soft ointments. Ski grip waxes covered with SHF powders freeze less and have higher speed qualities.

Usually the SHF powder is applied top coat on the rubbed grease (do not apply a thick layer), smoothed with fingers, rolled out by lightly pressing the cork. When used in combination with semi-solid lubricants, the powder can be carefully melted with one wire of the iron (do not rub with the cork afterwards). Clutch ointments can also be covered for short distances with SHF-100,200 emulsions.

I haven’t skied for a long time, it will definitely be 15 years, and maybe more from the moment when I last tried to ski on old wooden skis from a small hill in the yard. I also remember riding in the park during physical education classes, and after the house I diligently rubbed the surface of the ski with a candle for better glide.

A lot of water has flowed under the bridge since that time, but a miracle happened, about which I will probably write a separate article, and I got back on skis. I think the story is classic, I bought a set of ski equipment for the classics and at the end I asked the seller about the ointment, as I read it as always before buying and ointments were mentioned everywhere, the seller said you can do without it ...

A new day has come and I was impatient to try new skis in action, got ready and went to the ski track with anticipation of the pleasure of skiing and outdoor recreation. In fact, it turned out that I suffered for 40 minutes, got disappointed and went home, mentally encouraging myself that the ointment would correct the situation, which this article will be about.

Before buying, as always, I do this, I read on the Internet everything that could be read about how to choose skis correctly, but ointments are usually given little attention in articles on the choice of skis and this is very sad.

A lot of people are now skiing, parks and country ski slopes are all saturated with skiers, and parking lots are full of cars, some arrive, others leave, others change clothes, while others stand with thermoses and drink hot tea with cookies. Accordingly, every season, thousands of people are faced with the question of choosing skis, equipment, and about holding ointment. didn't hear at all.

On the one hand, this is true, because modern plastic skis Very good glide and really do not need lubrication for amateur walks. But there is one big “but”, because we are talking about the sliding of plastic, but there is a holding ointment, i.e. you can say braking, what it is, why it is, that's what we'll talk about.

A funny reality of reality, most of us do not know how certain mechanisms are arranged, how processes work, including most of the population do not know how is the movement on classic skis. When skating, you can guess both from the name itself, and simply by observing the technique and understanding the principle of repulsion if you have skated or skated before, but skiers who slowly slide along the ski track holding sticks in their hands look like they are just they rearrange their legs and slide, hence the question arises, why then the holding ointment, which will slow down the skis and they will stop going.

Why do you need ski hold ointment

Indeed, why smear the skis with an ointment that does not allow the surface to slide, if our parents and we all our childhood smeared the entire surface with paraffin for better glide?

The answer to this question lies in the technique of skiing with a classic move. Modern plastic skis have a curved shape and if you put them on a flat surface, we will see that the crap touches the surface, only in places close to the edges, and the middle is raised high. The middle or area that the skier's weight presses on while riding is called the last. With correctly selected skis, the block area is in contact with the ski track, only at the moment of pushing with the foot. To continue the thought further, I will make a brief footnote of how we actually ski.

How does the movement occur during the classic skiing

It is very clear to understand the technique of movement and its physics, if you imagine a rapidly accelerating skier no sticks. When skiing in the parks, I see a lot of people who simply rearrange their legs and push off with sticks, most likely they do not understand the technique of skiing. It is necessary to understand the simple rule that the movement occurs due to the alternating repulsion and subsequent removal of weight from the ski and sliding by inertia.

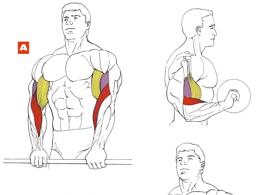

The arched area of the pad is designed to allow the applied on it holding ointment did not slow down the movement during the removal of the pushing force from the ski. At the moment of kick, most of the athlete switches to one ski, bends the block and the ski touches the ski track with its entire surface, ointment keeps the ski from kicking back during the push.

So we see that the grip wax allows you to push forward without the ski slipping backwards.

Choosing a grip wax for plastic skis

I hope that now you have a better understanding of how the classic move works. On that day, when, after the purchase, I rather hurried to the park on the ski track, I just didn’t know the technique of movement and its physics, and 40 minutes of torment consisted in the fact that I was driving off only with sticks, when I tried to push off with the ski, I received feedback, slippage and didn’t move, and minimal climbs turned into insurmountable obstacles, I think it looked funny from the outside ...

There are a lot of different holding ointments in stores, both in consistency (liquid and thick ointments), as well as in use temperatures, the latter disappointed me completely, since I ride as an amateur, the weather is constantly changing constantly in terms of temperature, so the prospect of having several different ointments with the need to apply every time the temperature changes, depressing.

And so I saw universal holding ointment, not a thick ointment, but in a convenient bottle with a sponge at the end with a declared use temperature from +0 to minus 20 degrees Celsius. I decided to take a chance, the amount is small and I bought it, but in my opinion it is better than buying several different ointments, but how will it show itself on the track?

I sanded the pad area with very fine sandpaper and began to apply holding ointment, this is done only in a warm room, since at low temperatures the liquid ointment becomes very thick and it will be unrealistic to apply it from a tube. Therefore, it is best to put it on the battery, heat it up, and then slowly apply it to the pad area, preferably in several layers.

I smeared the skis with holding ointment and went to the pine forest, I didn’t know if there would be a ski track, but knowing how beautiful and big it was, I really hoped for it.

My hopes were not in vain, a fabulously beautiful winter forest and many kilometers of ski tracks were waiting for me, where you can easily get lost and, most importantly, there were no people. That is why I bought skis for classic skiing, and not a snowboard as I wanted for a very long time, I’ll probably write a separate article about what to choose better snowboard or skis, this question is asked by many before each season and I think I found the answer to it, but about it in another article.

Skis went or my review of holding ointment

Skis go! I was finally able to fully push off with my feet, first of all, in order to hone the technique, I just took the sticks in one hand and rode without them, it turned out to go almost at the same speed as with sticks, i.e. all movement was achieved by repulsion from a slippery track.

How good is an all-purpose holding wax compared to fixed temperature waxes? You need to understand that everything is universal Always inferior in capabilities to narrowly focused, special ointments, the same rule works essentially everywhere. But, if you are an amateur and skiing leisurely for pleasure, then it is better to stop your choice on universal ointments, you already have to choose thick or liquid ones, I decided not to bother and it is very convenient for me to apply ointment from the bottle at home without getting my hands dirty.

In any case, if your skis are without notches, you will need a holding ointment. If you ski only in certain weather, you can take the ointment at a fixed temperature of -2 ... -5, this temperature is considered the best for classic skiing.

A couple of months have already passed, I repeatedly applied the ointment over the old one, removing only adhering leaves and branches. Wash off the old ointment before applying a new one in my opinion impractical unless you're a ski nut. Just roughen the surface of the block area with sandpaper, apply ointment, and at the next new exit from the house, inspect the skis and if it seems to you that there is not enough ointment left, just apply a new layer, for me personally it doesn’t go anywhere and I don’t see any point in exhausting by washing off the old layer with a solvent.

I hope my article was useful to you and now your skiing holiday will be only a pleasure. Try to go out of town to the forests, there will definitely be a ski track and walks through a quiet winter forest cannot be compared with skiing in city parks. As always, I'm glad your comments and reviews, you can ask questions or supplement the article with your information, I wish you good luck.

Before we talk about what domestic and imported ointments exist, we will give some advice on how to determine the condition of the snow, on which the choice of ointment depends.

Snow dry, freshly fallen at temperatures below 0 ° can be loose, powdery. If; this snow continues to lie and new is not added, then it is characterized as stale, old, hardened on the track. At temperatures above 0°, the snow melts. Wet freshly fallen snow can form a gloss on the ski track.

It is not easy to pick up an ointment for wet falling snow (at a temperature of 0 °, +1 °). In windy frosty weather, a windy and icy crust forms. But after the thaws are replaced by frosts, coarse-grained snow forms. If the weather is constantly frosty, then the snow becomes old - dry; stale, hardened. In the spring, after a thaw, ice forms, especially at a temperature of 0 °.

Depending on the condition of the snow and the air temperature, ski waxes are “marked” with labels of various colors. Changes to the color of the ski wax itself.

Ski ointment significantly improves sliding and helps to preserve the sliding surface from wear.

There are solid ski ointments, semi-solid and liquid.

Solid ointments are used in frosty weather, when the snow is dry and the air temperature is minus 1-2 ° and below.

Semi-solid ointments are mainly required in such weather when the air temperature is from -1 to +1 °. They are especially good in sticky wet snow. They can be combined with other ointments.

Among liquid ointments, two groups are distinguished: ointments of the "klister" type and the "scar" type. When applying these ointments, you must use a blowtorch or a special iron.

Domestic ointments are produced under the name "Visti" and "Temp".

Solid ointments:

"Visti": red - for temperatures from -1 to -3 °, blue - from -3 to -10 °, green - from -10 to -18 ° and yellow - from -18 ° and below.

"Temp": orange (C) for temperature from -1 to -7°, red (B) - from -4 to -14°, green (A) - from -12 to -28°.

Semisolid ointments:

"Visti": orange - used for fresh snow and temperatures from 0 to + 1 °, purple - for old, dry, stale snow at temperatures from 0 to - 1 °.

"Temp": brown (G) - for temperatures from -1 to +3 °.

Liquid ointments:

"Visti": red - for wet, freshly fallen snow; yellow - for wet, old, stale snow; black - for wet coarse snow.

"Temp": red (D) - during a thaw, green (E) is applied to the ski for its primer, after which another ointment is applied on top.

There are imported ski waxes: Finnish-made Rex and Wauhti, Norwegian-made Swix, Swedish-made Exelite, and Italian-made Rode.

Before applying the ointment, the sliding surface must be thoroughly cleaned and the old grease removed with a rag, after preheating the ski with a blowtorch or over a gas burner. The ski must be dry and well tarred. It is best to apply the ointment on the ski in a warm room, and after lubrication, put it outside to cool for 15-30 minutes (depending on the air temperature, the more frost, the less time it takes to cool the ski).

For sliding, it is not indifferent what layer of ointment is applied to the ski. A thin layer of ointment gives good glide, and a thicker one gives better grip on snow. At low temperatures, the skis are lubricated with a thin layer of solid ointments. If you have a long walk, then you should first apply the primer, and then take the skis outside, cool them down and bring them back into the room in order to spread them with a solid ointment.

I. Should I buy notched skis?

This is a question to which, alas, there is no single answer. I can only tell you quite definitely - it is notched skis that are used by more than half of the population of our planet on skis, and this figure, you see, says a lot. The advantages of using notched skis are more than obvious - you will never need to bother yourself with the question of how to oil the skis. Agree, such a formulation of the question captivates - he took the skis, got up and went.

The cons are just as obvious. Such skis will hold well on soft loose snow, and will not hold on more or less hard tracks. And, the most offensive, if notched skis do not hold, it is almost impossible to smear them.

I will say right away that I am not a fan of using these skis and from an early age I taught my children to smear skis. This is a more difficult option, which guarantees, however, normal riding in any weather. However, the final choice is still up to you, and the article below is addressed to those who have made their choice in favor of "regular" skis, and are faced with the question of how to spread them.

II. Ski lubrication kit of two, three, sometimes four jars of ointment, rubbing plug, scraper.

This is the most minimal kit you may need to lubricate your skis. To ski in a classic style, the skis must be smeared under the block with a holding ointment. The block is the middle part of the ski, starting from the heel of the boot and located 15-25 cm upwards from the mount. It is this middle part of the ski (block) that must be smeared with holding ointment so that your skis do not slip when you push your foot back.

For the first steps, a set of inexpensive domestic or imported ointments is quite suitable for you - it usually consists of four briquettes, sometimes jars made of thick metal foil or soft plastic. You will also need a synthetic rubbing cork. It is quite enough to buy a set of 4 ointments and smear the skis only under the block, rubbing them with a cork.

So, having smeared the ski under the block with ointment, it (ointment) should be rubbed with a rubbing stopper. Ideally, after rubbing, you should get an even, slightly shiny layer.

If for some reason an even layer does not work out, do not bother with this circumstance, it is quite enough to simply smooth the ointment.

Now about one more nuance. If you are going skiing in the woods, it is advisable to always take with you a warmer and colder ointment than the one you just put on, as well as a cork and a scraper. Consider the two most typical cases of missing the ointment.

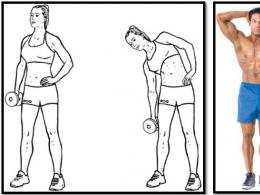

1. Skis do not hold, or, as skiers say, they “give away”, that is, they do not allow you to push confidently, when you push with your foot, they slide back. In this case, it is enough to put a warmer ointment under the block on top of the old one and rub it with a cork, and the situation will be corrected - you can again enjoy riding. It will take you only a couple of minutes to correct the lubrication.

2. Skis, as skiers say, “stupid”, that is, they don’t go at all, and sometimes they are also covered with ice or snow under the block - in that middle part of the ski where you applied too warm ointment. Skiers call this situation “sticky” if snow sticks to the wax, or icing if ice forms on the wax. There is a way out, you just need a little more time.

So, if ice or snow has formed under the block, peel them off with a scraper. If there is no scraper, this can be done with a branch, the tip of a ski pole, the key to the apartment, the edge of another ski, etc.

After that, intensively rub the ski block first with a glove, removing the lubricant from the remaining snow and moisture droplets, and then intensively with a cork, warming up and, as it were, drying the ointment. You will have to apply much more effort compared to rubbing in a warm room. Now that the ointment has dried and warmed up, you can put an additional layer of colder ointment on top of the unsuccessful lubrication. As a rule, in 99 percent of cases, this technique corrects the situation and allows you to continue walking through the forest.

III. Consider a specific example: how to smear skis at minus five degrees?

For example, the temperature outside is minus five degrees. You have a set of ski ointments "Visti", consisting of five briquettes. The most logical option for lubricating skis at minus five degrees below zero would be to smear with blue ointment - 2 - 8. However, remember the golden rule: you should always take two briquettes (cans) of border ointments in your pocket or pouch for a ski trip. In this case, it will be - 0 - 2 (purple ointment) and - 5 - 12 (light green). This way, whether it's warm or cold, you can adjust your lubrication and enjoy your skiing.

When you return home, remove the old wax from the ski with any plastic scraper (a piece of a plastic ruler, an old audio cassette case, etc.). After that, you can safely apply new grease to the remnants of the old grease. If you want to clean the skis clean (which, in general, is completely optional), this can be done with a piece of cotton soaked in gasoline or turpentine. If funds allow, buy a normal plastic scraper and a bottle of branded cleanser.

IV. A set of liquid ointments, a wash, a scraper for skiing in positive weather.

As I said, four inexpensive cans of ointment, a scraper and a grinding plug will be enough for you for almost all occasions. But there are situations when there is still a lot of snow, and the air temperature is already steadily positive. Sunday, sun, drops drive you out into the street with your skis, you smear yourself with the warmest of the briquettes of ointment you have, and the skis ... categorically do not hold, they “give away”. It's a shame? And how! And, nevertheless, there is a way out of this situation, and it is quite simple - buy a tube of universal liquid ski wax (skiers sometimes call liquid ski wax klisters) and get a bottle of wash (gasoline, kerosene, turpentine). I want to warn you right away: buying liquid ski waxes will put you in the category of slightly more advanced skiers, because handling them will require a little more fuss and experience. But the gain in the form of comfortable skiing on the spring track will be simply incomparable.

So, you will completely manage with a set of two tubes of liquid ointment - red (plus) and purple (zero and a slight minus). We smear ourselves with red ointment at any positive air temperature, and purple - at zero and a slight minus. It is important to understand here that spring snow is almost never soft and fluffy, like in winter. As a rule, in spring it consists of hard large snow-ice granules. Skiers call this snow firn. For such icy snow in sub-zero weather, you need a purple klister.

How to smear skis with liquid ski wax? This should be done in a warm room, evenly squeezing greasy drops of ski ointment onto the block (middle part) of the ski and then rubbing this ointment with a scraper.

And now about why you have to fiddle a little more with liquid ski waxes compared to solid ones (jars or briquettes). The fact is that liquid ski ointments, which in their consistency are very reminiscent of condensed milk, tend to stain hands and clothes, and in order to avoid these sad consequences, after training, the skis should be immediately cleaned with a scraper, and then with a wash. The second option is to pack the skis in a case, bring them home and clean them there. And yet, most skiers prefer to clean their skis immediately after the end of the workout - there are fewer soiled clothes and sticky hands, and the ski bag does not get dirty from the inside. The obligatory need to clean the skis after a walk is perhaps the only inconvenience of using liquid ointments. But the constant companions of liquid ointments are usually the spring sun, a wonderful ski track and a wonderful mood. So, believe me, the game is worth the candle.

V. Economy kits of ointments for lubricating skis.

As a rule, all leading manufacturers put on sale economical ski wax kits containing two or three cans of solid wax and a grinding stopper.

Sometimes this kit also includes one or two tubes of liquid ointment, a scraper. It happens that this kit is packaged in an inexpensive waist bag (skiers say “pouch”), and sometimes it also includes a spray bottle with a wash. This is a very good option for solving all your ski lubrication problems for the next few years in one fell swoop, so be sure to use it if possible.

VI. Glide ointments, or, as they are also called in Russia, paraffins for lubricating skis.

This is an area that I strongly discourage you from trespassing. Trust me, modern plastic skis glide beautifully over the snow without any special treatment. This glide is enough for your eyes for any, even the longest walks through the forest in any weather.

Therefore, you can forget about the ends of the skis (that is, what is located above and below relative to the block - the middle part of the ski) and do not process them with anything.

Another thing is if your walks in the forest have brought you to such a state that you want to go to the start of, say, the 50-kilometer Moscow ski track or, more than aspirations, test yourself in a very difficult classic MVTU Race.

In this case, you already need to learn how to paraffin skis, you need to acquire not only a set of slip ointments (paraffins), but also an iron, a brush, a hard metal scraper, a ski preparation machine, etc. But these are pleasant chores. It means that you are already firmly “hooked on the needle” of cross-country skiing, which means that skiing has already become a very important part of your life for you. But this time we will not talk about all the intricacies of preparing skis with glide waxes - this is beyond the scope of our conversation today.